Nambu Tekki, cast ironware from Iwate Prefecture, Japan, boasts a rich history spanning nearly nine centuries. This traditional craft, passed down through generations, involves meticulous pouring, smoothing, and grinding of molten iron, resulting in pieces that are both functional and aesthetically pleasing. The enduring appeal of Nambu Tekki lies not only in its quality but also in the compelling story woven into each piece, a testament to the artistry and cultural heritage of the region. For those interested in exploring the elegance and craftsmanship of Japanese cast iron, consider exploring our collection of exquisitely crafted tea sets; you can find them here: .The evolution of Nambu Tekki showcases a fascinating blend of ancient techniques and modern innovation. While traditionally rust-proofing involved a charcoal firing process, a fifth-generation artisan, Oika, revolutionized the technique using an electric kiln and nitrogen gas, creating a remarkably thin and durable rust-resistant coating. This fusion of traditional craftsmanship and scientific research not only enhanced the longevity of Nambu Tekki but also significantly improved its performance in the kitchen, offering superior heat distribution and cooking results.

Pros And Cons

- Long history (approx. 900 years)

- Rust-resistant due to new anti-rust treatment using electric kiln and nitrogen gas to create a thin iron oxide coating (10 micrometers)

- Thin oxide coating is supple and withstands expansion and contraction of iron under heat

- Produces even cooking and a crispy exterior on food

- Traditional rust-proofing (black rust) can wear off with scrubbing

- Red rust can still appear despite rust-proofing

Read more: Experience the Elegance: 9 Japanese Cast Iron Tea Sets

A Legacy Forged in Fire: The History of Nambu Tekki

Nambu Tekki, cast ironware from Iwate Prefecture, boasts a history spanning nearly 900 years. This traditional craft involves pouring molten iron into molds, followed by smoothing and grinding the surface. The process is steeped in history and passed down through generations, reflecting a deep connection to the region's heritage.

The resulting ironware, initially rough, transforms into elegant, functional pieces. These items aren't simply kitchen tools; they represent a tangible link to centuries of skilled craftsmanship and cultural significance. Their enduring appeal speaks to both the quality and the story behind each piece.

Traditional Rust-Proofing: The Black Rust Process

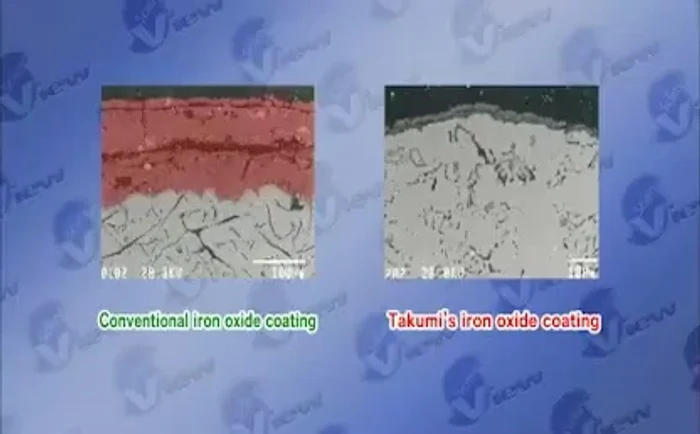

Traditionally, rust-proofing Nambu Tekki involved firing the iron at approximately 900 degrees Celsius in burning charcoal. This process creates a layer of black rust, an iron oxide coating, which prevents the more damaging red rust from forming. Black rust's resistance to water makes it an effective barrier.

However, this traditional black rust coating, while effective, can be susceptible to damage if scrubbed too vigorously. This limitation spurred the development of a more durable and refined anti-rust method.

A Modern Marvel: The Innovative Rust-Resistant Treatment

Oika, a fifth-generation Nambu Tekki artisan, developed a revolutionary anti-rust technique using an electric kiln. By injecting nitrogen gas to expel oxygen, and then introducing low-concentration oxygen at high temperatures, he created a remarkably thin iron oxide coating.

This thin coating, measuring only 10 micrometers, is significantly more supple than the traditional 100-micrometer coating. Its flexibility allows it to withstand the expansion and contraction of the iron during heating and cooling, preventing cracking and enhancing durability.

Serendipitous Discovery and Collaboration

Oika's breakthrough wasn't a planned achievement; it was a serendipitous discovery. Tests conducted by Iwate University revealed that the unexpectedly thin iron oxide coating on his experimental pieces was exceptionally rust-resistant.

The collaboration between the artisan and the university underscored the power of combining traditional craftsmanship with modern scientific research. This innovative approach has revitalized the Nambu Tekki tradition, enhancing its functionality and appeal.

Culinary Excellence: The Performance of the Innovative Ironware

Chef Yasukotsu Ito, a fan of Oika's pans, showcased their exceptional cooking capabilities. The pans deliver perfectly golden-brown, crispy-skinned dishes, a testament to the even heat distribution and superior performance offered by the innovative rust-resistant coating.

The combination of traditional techniques and modern enhancements creates cooking vessels that not only look beautiful but also function flawlessly. This successful fusion of legacy and innovation underscores the lasting value of Nambu Tekki.

Conclusion: A Modern Classic

Oika's innovation demonstrates a successful modernization of a venerable tradition. His rust-resistant Nambu Tekki represents a perfect blend of time-honored methods and cutting-edge techniques. The thin, supple oxide coating, achieved through precise control of oxygen levels, enhances both the durability and performance of the cookware.

The resultant cookware not only retains the beauty and history of Nambu Tekki but also excels in functionality. Its superior performance, combined with a captivating story, makes it a highly desirable and innovative product, well-suited for modern kitchens.