A sharp knife is more than just a kitchen tool; it's an investment in efficiency, safety, and culinary creativity. But how long can you expect your prized blade to maintain its edge and overall functionality? The lifespan of a knife isn't simply a matter of years; it's intricately tied to the quality of materials, the care it receives, and the frequency of use. From budget-friendly options to high-end chef's knives, understanding the factors that influence longevity is crucial for making informed purchasing decisions and maximizing the return on your investment.

This comprehensive guide delves into the science of knife longevity, exploring everything from steel type and construction to proper sharpening and storage techniques. We'll break down the process step-by-step, offering practical advice to ensure your knives remain a reliable and indispensable part of your kitchen arsenal for years to come. Learn how to identify potential problems, implement preventative measures, and ultimately extend the life of your blades.

Preparation and Safety Guidelines

- Various knives (budget, mid-grade, high-end)

- Never put knives in the dishwasher. The high heat and harsh detergents can damage the blade and handle, significantly shortening its lifespan.

- Always store knives properly. Use a knife block, magnetic strip, or sheath to prevent chipping, dulling, and accidental injury.

- Sharpen your knives regularly. A sharp knife is a safer knife and requires less force to cut, reducing wear and tear on the blade.

Step-by-Step Instructions

Initial Considerations

- Consider the knife's price and manufacturer.

- Use the knife for its intended purpose. A lightweight EDC knife is not suitable for heavy-duty tasks.

Initial Considerations Break-in and Use

- Account for the initial break-in period. Many users are hesitant to use a new knife immediately, delaying its lifespan calculation.

- At least 100 flips and light cuts (cardboard, etc.) before heavy use to allow the lock bar to settle and strengthen.

- Gradually increase the intensity of tasks performed with the knife.

Break-in and Use Build Quality Assessment

- Pay attention to the hardware (liners, stop pins), their size, and how well they support the blade's weight. Larger, more robust hardware generally leads to better longevity.

Build Quality Assessment Lock Mechanism Analysis

- The angle and strength of the lock bar in relation to the lock face significantly impact the knife's performance and lifespan. A well-designed lock face and lock bar interaction prevents premature lock wear and potential failure.

- Different lock types (e.g., liner lock, frame lock, axis lock) have varying strengths and weaknesses. Understand the specific lock's characteristics.

Lock Mechanism Analysis Material and Geometry

- Sharpening frequency and blade durability depend on the steel type. Higher-end steels (e.g., M390, K390) generally offer better longevity than budget steels (e.g., 440C).

Material and Geometry

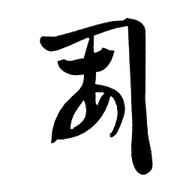

Read more: Mastering the Art of Water Stone Knife Sharpening: Achieve a Razor-Sharp Edge

Tips

- Don't overload your knife right away; build up its usage gradually.

- Regular maintenance, proper sharpening, and using the knife for its intended purpose are crucial for maximizing lifespan.